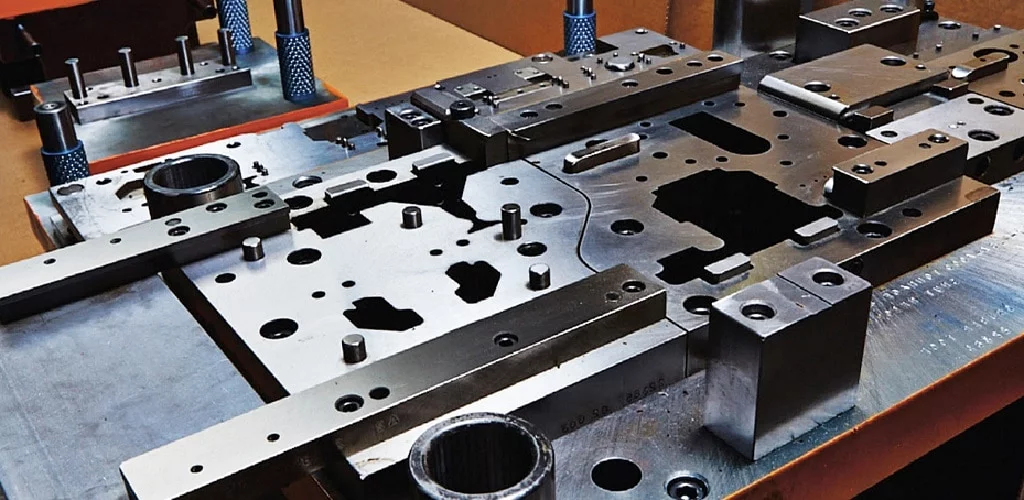

Tool & Die Services

Precision tools. Reliable performance.

From concept to press-ready tooling, we design and build custom dies that ensure dimensional accuracy, repeatability, and cost-efficiency for high-volume manufacturing.

Let’s talk tooling →

Precision tools. Reliable performance.

From concept to press-ready tooling, we design and build custom dies that ensure dimensional accuracy, repeatability, and cost-efficiency for high-volume manufacturing.

Let’s talk tooling →

Tool and die engineering is the foundation of accurate and efficient manufacturing. It involves designing and building custom dies, fixtures, and tooling that enable high-speed, high-volume metal forming.

From prototyping to full-scale production, our in-house team creates tools tailored to your specifications. Whether you're stamping, forming, or cutting — precision tooling ensures every part fits, functions, and lasts.

Discuss your project →CAD-led precision designs backed by FEA simulations ensure tooling that performs under pressure.

Full-control toolroom builds dies and jigs to spec, accelerating iterations and ensuring consistency.

Routine servicing and fast rework reduce tooling downtime and extend tool life for continuous output.

From early prototyping to high-volume runs, we streamline the tooling path to full-scale production.