Custom metal stamping

Precision at its core

From low-run tooling to high-volume output, Formstar delivers stamped components that meet your specs with speed, accuracy, and scalability.

Request a free quote →

Precision at its core

From low-run tooling to high-volume output, Formstar delivers stamped components that meet your specs with speed, accuracy, and scalability.

Request a free quote →

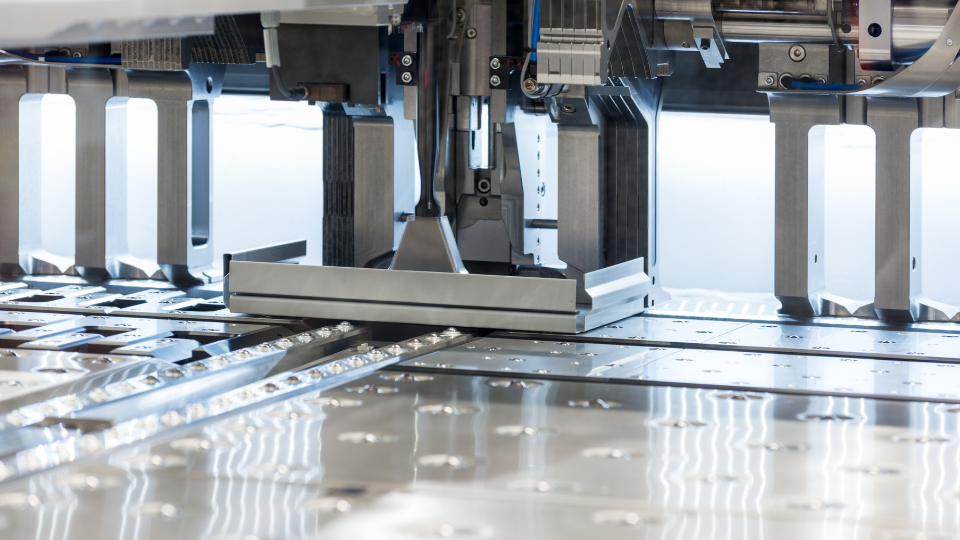

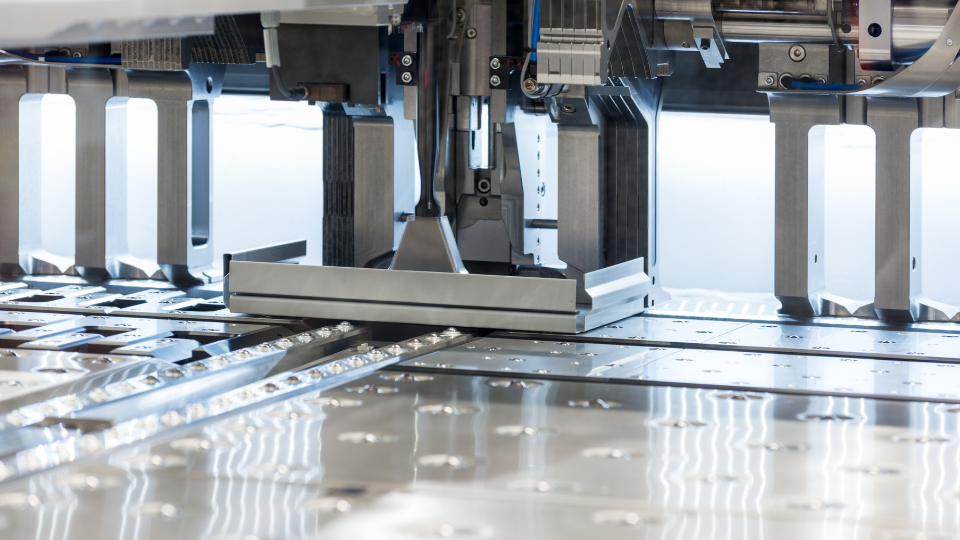

Custom metal stamping is a high-precision manufacturing process that converts flat metal sheets into specific shapes through specialized tooling and hydraulic or mechanical presses. This method is ideal for producing large volumes of identical parts with exceptional accuracy and efficiency.

At Formstar Industries, we leverage advanced technology and deep expertise to deliver consistently high-quality stamped components across a diverse range of industries, including automotive, electronics, medical, and consumer goods. Our focus is on meeting your exact design and performance criteria.

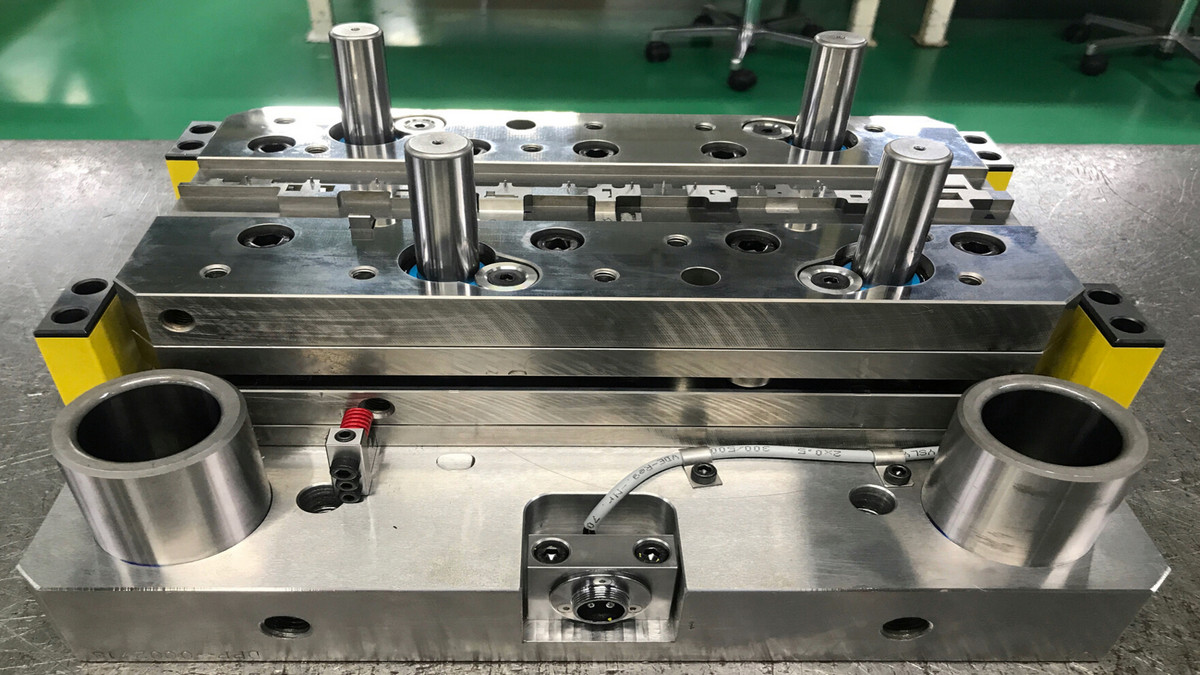

Discuss your project →Combines multiple operations like cutting and bending in one press — ideal for complex parts at high volume.

Shapes flat sheets into deep, hollow parts — perfect for seamless, pressure-resistant components.

Executes multiple cuts/forms in one go — great for clean-edged, flat parts with tight tolerances.

Optimized for massive output — fast, accurate presses for small parts like terminals, clips, and contacts.